The production process

The production of our alcohol-free apple wine "Rocco" is carried out with the utmost care and dedication to preserve the natural aromas and the vibrant color of the red-fleshed apples. We place great emphasis on quality and sustainability.

1. Harvest and Selection of Apples:

Our red-fleshed apple varieties are harvested at the optimal ripening time at the end of September. The apples are distinguished by their intense color and unique flavor, which gives our Sparkling Rocco its special freshness.

2. Pressing and Juice Extraction:

The apples are carefully washed and then gently pressed to obtain the fresh apple juice. We ensure that the natural color and aromas are fully preserved.

3. Storage:

The obtained apple juice is stored in cooled and sterile tanks until bottling.

4. Filtration and Bottling:

Before our Sparkling Rocco can be bottled, it is gently filtered to ensure that the natural red color is not lost. Subsequently, the juice is infused with carbon dioxide using a pressure tank process. This process takes several days, during which the juice is always kept cool.

After impregnation, the juice is filled into our bottles and sealed.

5. Pasteurization:

To make our Sparkling Rocco preservative-free and shelf-stable, we pasteurize it. Here, the temperature of the juice is raised to 82 degrees Celsius. This allows us to guarantee a shelf life of up to 2 years.

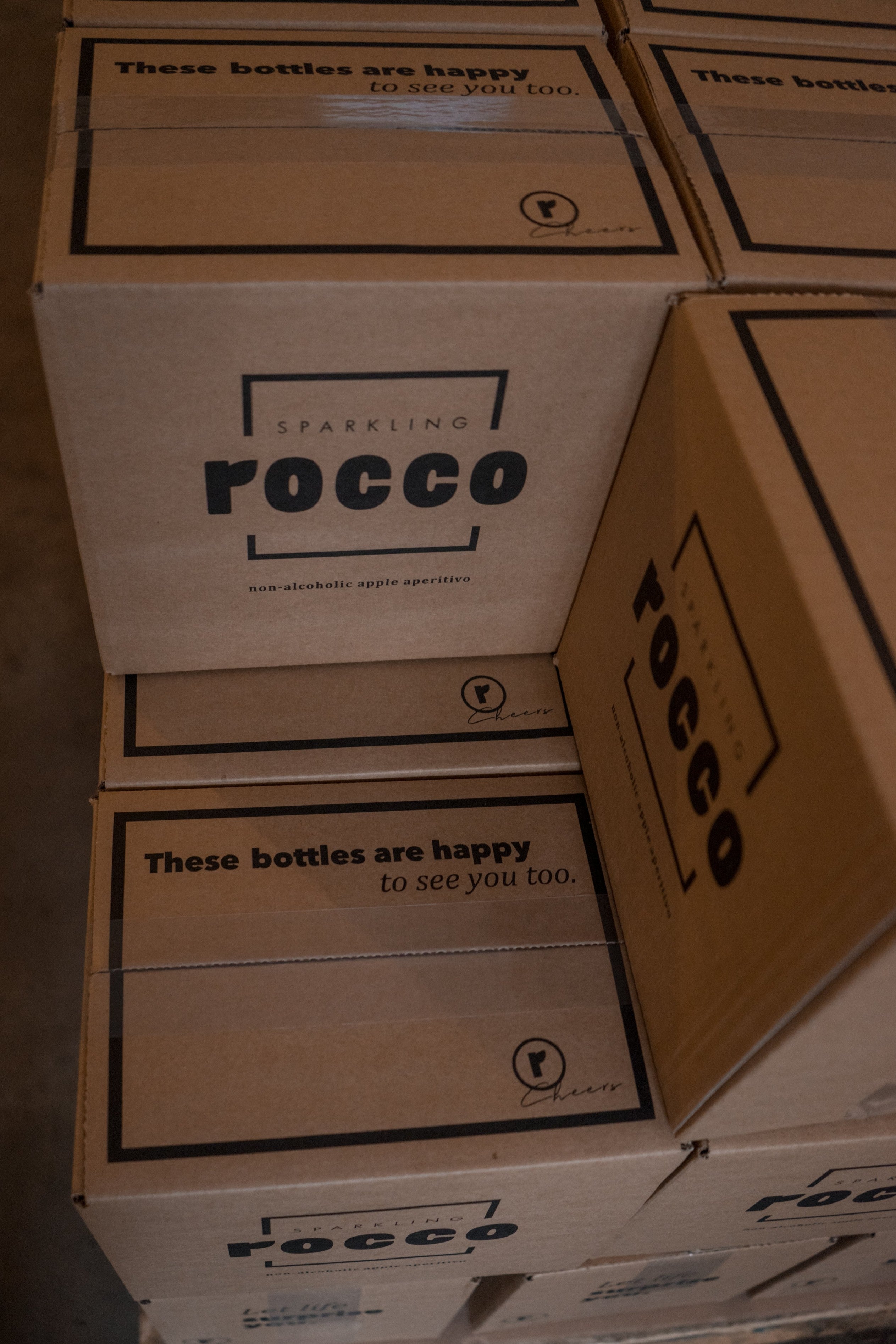

6. Labeling and Packaging:

After pasteurization, the bottles are rinsed with cold water, dried, and can now be labeled. Here the Rocco label is applied, as well as the shrink capsule.

Afterwards, the bottles are packed into cartons and palletized. Now Sparkling Rocco is ready for delivery to our valued customers.

With Sparkling Rocco, we offer you a refreshing apple secco that delights not only as an aperitif but also as a companion to various dishes. Enjoy the natural taste of South Tyrol in your glass.